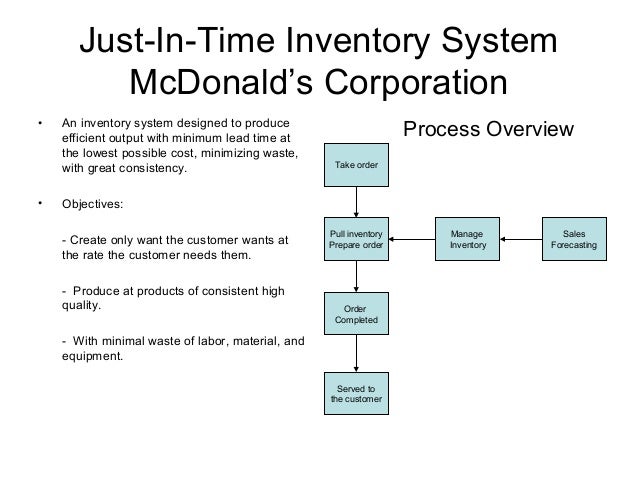

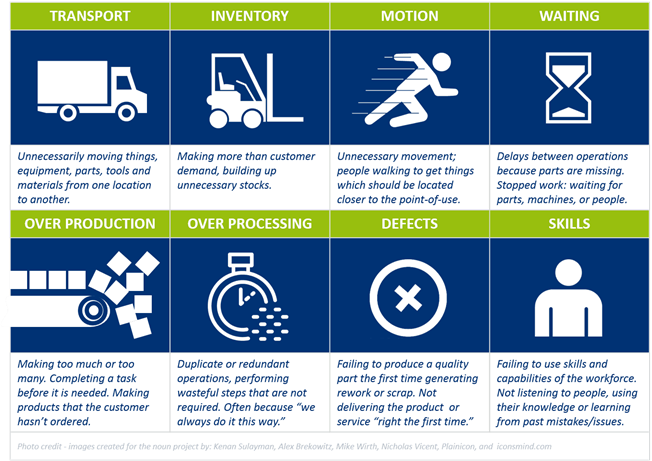

Anything that doesn’t contribute to the product’s value to the customer is considered inefficient.Īnother key to lean is its definition of waste, of which there are eight types: The idea is to refine internal processes as much as possible to give consumers the highest value possible in a product or service. Perfection: Relentlessly pursue perfection by constantly engaging the problem-solving process.Pull: Flow is made possible by “pull,” or the idea that nothing is made before it is needed, thereby creating shorter delivery cycles.Flow: All product processes flow and synchronizes seamlessly with each other.Value Stream: What goes into maximizing value and eliminating waste throughout the entire process from design to production.Value: Understand what customers value in a product or service.Fundamentally, the method emphasizes the idea of “continuous improvement.” Lean thinkers who brought the methodology from Japan to the West (specifically James Womack and Daniel Jones) specified five core principles: Though search inquiries on lean methodology will immediately bring “eliminating waste” to the front, this is not the complete definition.

The term "Lean" was popularized by James Womack and Daniel Jones in their book "The Machine That Changed the World." Lean principles have since been adopted in various industries beyond manufacturing and have become a widely used approach for continuous improvement. The goal of Lean was to eliminate waste and improve quality and efficiency. It was developed to respond to the inefficiencies and waste of traditional mass production methods. Lean methodology originated in the Japanese automobile industry in the late 1940s and 1950s, specifically at Toyota Motor Corporation.

0 kommentar(er)

0 kommentar(er)